Industrial Coffee Mill Overview: Boost Performance and Quality

In the affordable landscape of coffee manufacturing, choosing the ideal commercial coffee mill plays an essential role in improving both effectiveness and item high quality. Recognizing the nuances of various mill types and crucial functions-- such as customizable work setups and durable building and construction-- can significantly affect the last taste profile of the coffee. Moreover, the optimization of the grinding process, coupled with attentive upkeep, is crucial for maintaining efficiency with time. As we explore these crucial aspects, it comes to be apparent that the effects expand beyond plain equipment choice, impacting overall service success in ways that necessitate closer assessment.

Understanding Mill Kinds

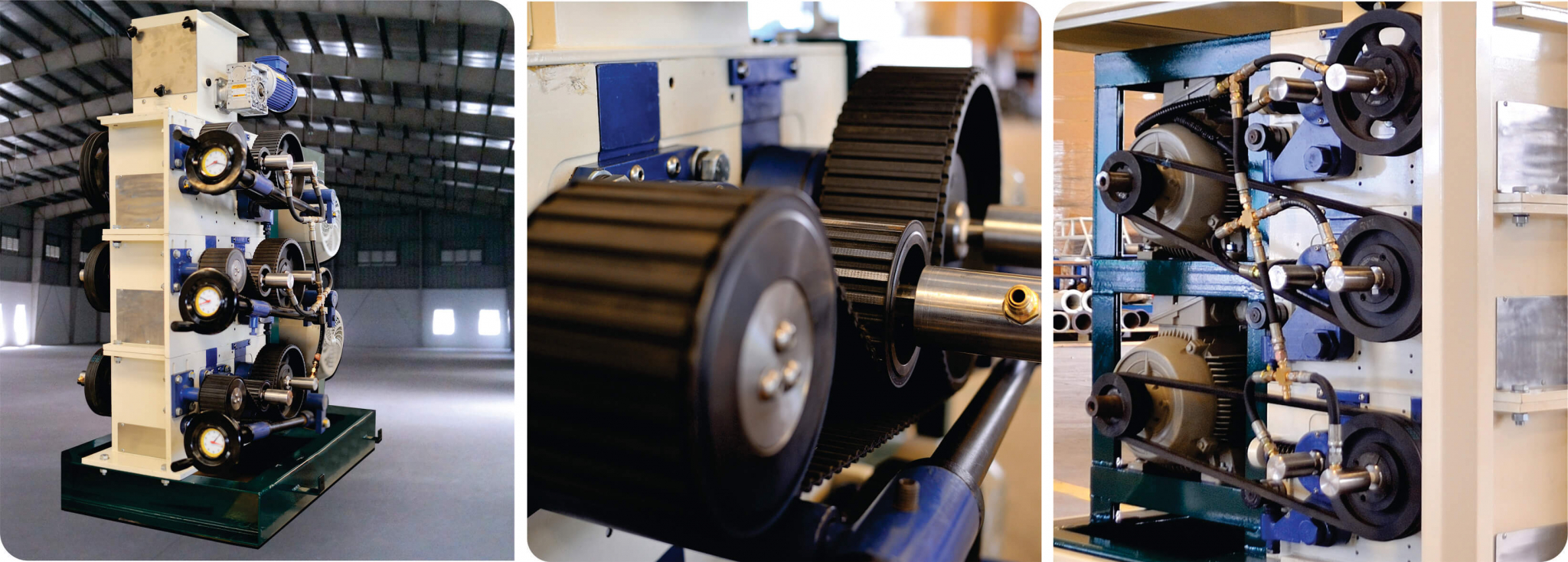

When choosing an industrial coffee mill, comprehending the numerous kinds offered is essential for enhancing both flavor removal and operational effectiveness. Both key sorts of mills are blade grinders and burr grinders. Blade grinders make use of sharp blades that slice coffee beans right into inconsistent dimensions, bring about uneven removal and possibly unwanted tastes. While blade mills are often a lot more appropriate and cost effective for small-scale procedures, they are generally not advised for industrial use.

Inevitably, selecting the best kind of mill is integral to maintaining top quality and effectiveness in coffee production, making it essential for companies to buy top quality burr mills for optimum outcomes.

Trick Features to Consider

Choosing an industrial coffee mill needs cautious consideration of numerous essential functions that can significantly affect both efficiency and the overall coffee experience. One of the main aspects to evaluate is the grinding system. Burr mills are generally chosen over blade grinders, as they provide a regular work dimension, which is critical for optimal removal and flavor.

Another important function is the mill's capability. A versatile mill with numerous setups permits you to customize the grind size to different developing approaches, boosting the coffee's taste profile.

Examine the grinder's noise degree, particularly in an active coffee shop or production environment, where excessive sound can be disruptive. Spending in a grinder that stabilizes these functions can significantly boost both operational performance and the quality of the coffee served.

Optimizing Grinding Refine

To achieve the most effective results in coffee prep work, enhancing the grinding process is essential. The grind dimension considerably affects extraction, taste, and general high quality of the made coffee. Various developing approaches call for details work dimensions; as an example, coffee demands a fine work, while French press demands a crude structure. Understanding the connection in between grind dimension and developing approach is the initial step in optimization.

Additionally, keeping an eye on the grinding rate can maximize the procedure. Slower grinding frequently generates less warm, protecting delicate flavors and scents. Alternatively, much faster grinding might create excessive warm, negatively affecting the coffee's high quality.

Maintenance and Care Tips

Correct maintenance and care his response of industrial coffee grinders are important for making sure optimum efficiency and long life. Normal cleaning is the structure of upkeep; deposit buildup can impact taste and grinding performance. It is advisable explanation to cleanse the mill after each usage, wiping down the exterior and eliminating any coffee grounds from the burrs.

Furthermore, check the grinding burrs for deterioration. Dull burrs can compromise work consistency, so they ought to be replaced as necessary. Industrial Coffee Grinder. Occasionally calibrating the grinder is additionally crucial, as this maintains the wanted grind size for numerous brewing methods

Lubrication of relocating parts should be executed according to the maker's specifications, as this minimizes friction and lengthens the life of the devices. It is important to make use of food-grade lubricating substances to make certain security and conformity with health and wellness regulations.

Last but not least, keep the grinder in a dry and secure atmosphere to stop corrosion and deterioration. By adhering to these upkeep and treatment tips, drivers can enhance the performance of their industrial coffee grinders while ensuring top notch outcome and expanded operational life.

Roi Evaluation

Reviewing the roi (ROI) for commercial coffee grinders is essential for companies seeking to maximize their coffee manufacturing capabilities. A detailed ROI analysis assists establish the economic viability of investing in high-grade grinders, allowing companies to evaluate the preliminary prices versus prospective gains.

Analyze the acquisition cost of the grinder, including installment and any type of required modifications to existing framework. High-performance mills often lead to lowered grinding time and raised throughput, which can substantially improve efficiency.

In addition, take into consideration the effect on product quality. Industrial Coffee Grinder. Superior grinders produce a more consistent grind size, which can improve taste profiles and consumer contentment, eventually driving sales. By enhancing the high quality of the last product, businesses can warrant higher prices, causing increased profits

Conclusion

In summary, a commercial coffee grinder plays a critical function in improving both efficiency and product high quality within coffee production. Eventually, the calculated financial investment in a dependable grinder contributes considerably to improved income and competitiveness in the coffee Get the facts industry.

In the competitive landscape of coffee production, picking the appropriate commercial coffee mill plays a crucial duty in boosting both performance and product quality. The two key kinds of mills are blade mills and burr grinders. Within the burr grinder classification, there are flat burr grinders and conical burr mills, each with its benefits. Burr mills are generally chosen over blade grinders, as they give a regular grind size, which is essential for optimum removal and flavor.

In summary, a commercial coffee mill plays a crucial role in enhancing both effectiveness and product quality within coffee manufacturing.